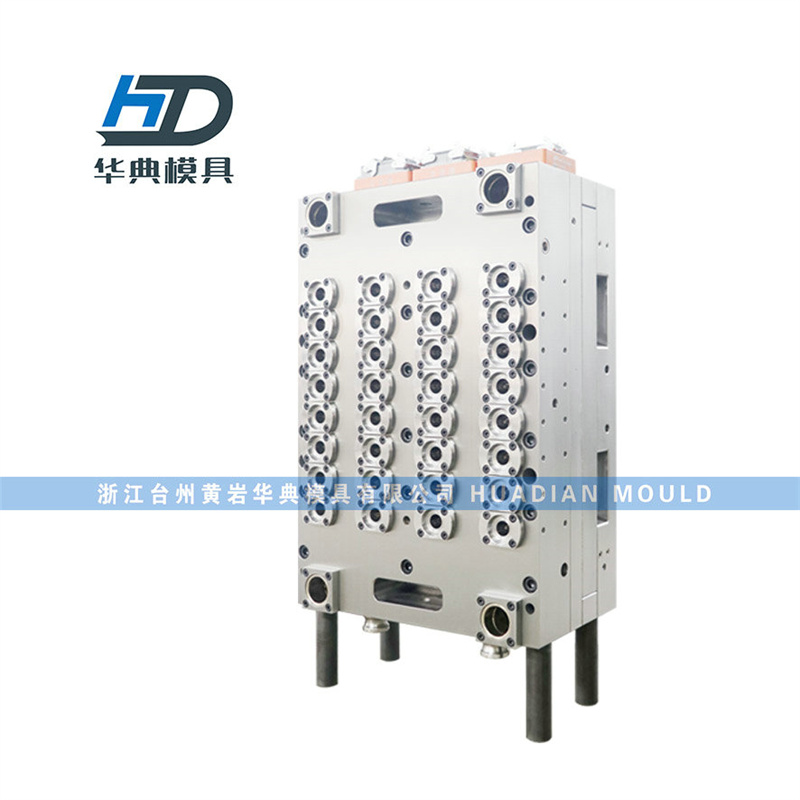

32 Kab noj hniav Disinfection ua pwm

Specifications

| Cavity | Ua | Pwm Loj | Pwm luj | Lub Sijhawm Sijhawm | |||

| Qhov hnyav (g) | Caj dab (mm) | Qhov siab (mm) | Dav (mm) | Thickness (hli) | (kg) | (sec) | |

| 2 (1 * 2) | 7 20 | 55 | 470 | 300 | 608 | 330 | 125 |

| 4 (2 * 2) | 7 20 | 55 | 490 ib | 480 | 730 ua | 440 | 130 |

| 8 (2 * 4) | 16 | 28 | 450 | 350 | 410 | 475 ib | 18 |

| 12 (2 * 6) | 16 | 28 | 600 | 350 | 415 | 625 | 18 |

| 16 (2 * 8) | 21 | 28 | 730 ua | 380 | 445 | 690 ib | 22 |

| 24 (3 * 8) loj | 28 | 28 | 770 ib | 460 | 457 ib | 1070 | 28 |

| 32 (4 * 8) loj | 36 | 28 | 810 | 590 ua | 515 | 1590 ib | 28 |

| 48 (4 * 12) hli | 36 | 28 | 1070 | 590 ua | 535 ib | 2286 ib | 30 |

Qhov kom zoo dua ntawm Hot Runner Technique

1. Txo qhov nkim thiab nqi ntawm cov khoom siv raw.

2. Txo kev ua haujlwm rau kev rov ua dua tshiab, kev faib tawm, tsoo, qhuav, thiab khaws cov khoom pov tseg, txhim kho kev ua haujlwm zoo, txuag sijhawm thiab chaw.

3.Tsis txhob siv cov khoom xa rov qab uas yuav cuam tshuam rau cov khoom zoo.

4.Guarantee cov khoom nyob rau hauv tib theem zoo

5.Increase lub ntim ntim, Txhim kho lub compressibiity ntawm yas yaj

6.Intesify qhov kev txhaj tshuaj muaj nuj nqi, txhim kho cov txheej txheem

7.Txo lub sijhawm ntawm kev txhaj tshuaj thiab kev tswj xyuas siab

8.Txo Clamping quab yuam

9.Shorten Pwm qhib stroke ntawm kev txhaj tshuaj, Tshem tawm lub sijhawm ntawm kev tshem tawm cov khoom Nozzle

10.Shorten lub voj voog txhaj tshuaj, txhim kho lub automation thiab ua hauj lwm efficiency

Qhov tseem ceeb Performance of Hot Runner System

1.Control qhov kub ntawm yas yaj precisely, tshem tawm cov degration ntawm cov ntaub ntawv.

2.Naturally balanced runner desgin, Pwm Cavity sib npaug.

3.Suitable loj ntawm Kub Nozzle tuaj yeem paub tseeb tias cov yas yaj txawb tau zoo thiab pwm kab noj hniav tau sau tusyees.

4. Kho lub rooj vag qauv thiab qhov loj tuaj yeem lav cov pwm kab noj hniav sib npaug, lub rooj vag valve kaw lub sijhawm, kom luv lub sijhawm voj voog.

5. Tsis muaj lub kaum sab xis tuag hauv kev sib tw, lav kom hloov cov xim sai sai, zam cov ntaub ntawv degration.

6. Txo qhov siab poob

7. Kev tswj xyuas lub sijhawm yog tsim nyog.

HuaDian Mould - cov ntaub ntawv pwm

| TSIS MUAJ. | Lub npe | Kev piav qhia | Hardness | |

| 1 | Pwm puag khoom | P20 | 28-32 : kuv | |

| 2 | Core, kab noj hniav | S136 | 48-52 : kuv | |

| 3 | Ntsia caj dab | S136 | 48-52 : kuv | |

| 4 | Txias hom | Pwm core, caj dab txias | ||

| 5 | Txias hom rau core phaj thiab kab noj hniav phaj | 1in,1 ua | ||

| 6 | Tawm ntawm qhov chaw (MM) | "+/- 0.08MM | ||

| 7 | Lub sij hawm txhaj tshuaj | 8-23 vib nas this | ||

| 8 | Lub sij hawm xa tuaj | 55 Hnub tom qab desgins paub tseeb | ||

32 kab noj hniav Disinfection Perform Pwm yog cov pwm txhaj tshuaj zoo uas tuaj yeem tsim ntau yam khoom siv tshuaj tua kab mob.Cov pwm no yog ua los ntawm cov ntaub ntawv zoo, nrog rau kev ua haujlwm ntev thiab kev ua haujlwm siab.Siv cov pwm no tuaj yeem txhim kho cov khoom tsim tau zoo, ua tiav cov khoom lag luam zoo thiab cov nplais, yog li txo cov nqi tsim khoom thiab txhim kho cov txiaj ntsig.

Cov pwm no muaj 32 kab noj hniav faib rau tag nrho cov pwm, uas tuaj yeem tsim ntau yam khoom siv tshuaj tua kab mob los ntawm kev txhaj tshuaj molding ib zaug, ua rau lub voj voog ntau lawm.Thaum nws siv, tsuas yog cov khoom siv raw yog txhaj rau hauv pwm, thiab lub tshuab txhaj tshuaj molding tuaj yeem pib tsim ntau cov khoom siv tshuaj tua kab mob kom tiav, nrog rau siab precision thiab zoo sib xws, uas zoo heev txhim kho cov khoom siv.Nyob rau tib lub sijhawm, cov khoom lag luam ruaj khov yog lav, kom cov neeg siv khoom muaj kev ntseeg siab.

32 Cavities Disinfection Ua Pwm muaj ntau yam zoo dua li kev tsim khoom.Nws siv lub tswv yim tsim kho siab heev, kom cov pwm tsim yog qhov tseeb thiab yooj yim rau kev sib sau.Cov ntaub ntawv zoo thiab cov txheej txheem tsim khoom tau lees tias nws lub zog ruaj khov thiab ua haujlwm tsis tu ncua thiab ruaj khov nyob rau hauv kev ua haujlwm siab zog.