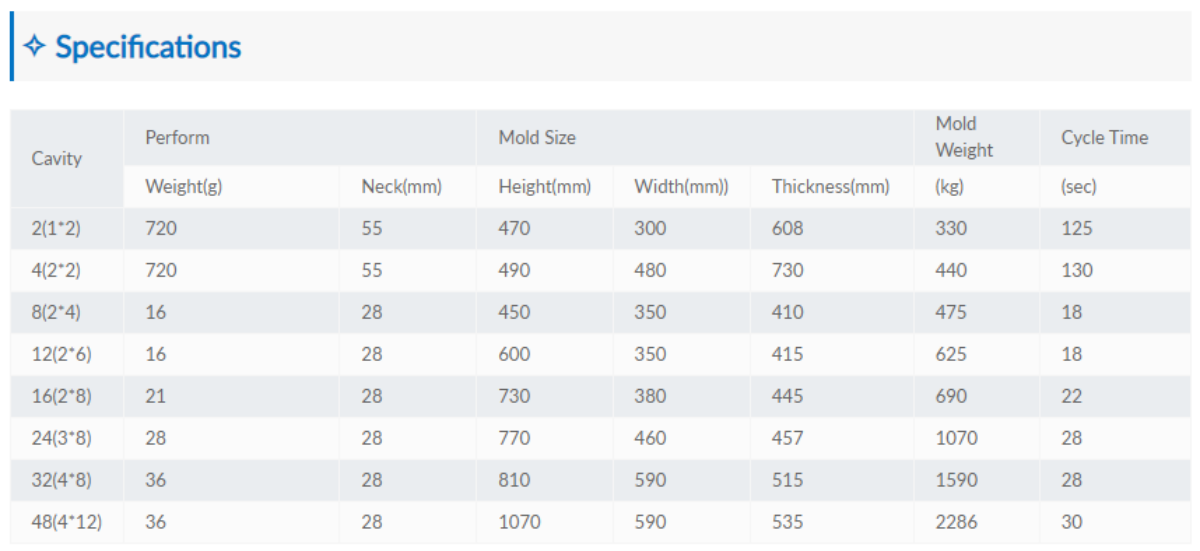

72 kab noj hniav dej lub raj mis preform loj pwm

Qhov Advantage On Kub Runner Technique

1. Txo cov khoom pov tseg thiab cov nqi ntawm cov khoom siv raw.

2. Txo kev ua haujlwm rau kev rov ua dua tshiab, kev faib tawm, tsoo, qhuav, thiab khaws cov khoom pov tseg, txhim kho kev ua haujlwm zoo, txuag sijhawm thiab chaw.

3.Tsis txhob siv cov khoom xa rov qab uas yuav cuam tshuam rau cov khoom zoo.

4.Guarantee cov khoom nyob rau hauv tib theem zoo

5.Increase lub ntim ntim, Txhim kho lub compressibiity ntawm yas yaj

6.Intesify qhov kev txhaj tshuaj muaj nuj nqi, txhim kho cov txheej txheem

7.Txo lub sijhawm ntawm kev txhaj tshuaj thiab kev tswj xyuas siab

8.Txo Clamping quab yuam

9.Shorten Pwm qhib stroke ntawm kev txhaj tshuaj, Tshem tawm lub sijhawm ntawm kev tshem tawm cov khoom Nozzle

10.Shorten lub voj voog txhaj tshuaj, txhim kho lub automation thiab ua hauj lwm efficiency

Qhov tseem ceeb Performance Of Hot Runner System

1.Control qhov kub ntawm yas yaj precisely, tshem tawm cov degration ntawm cov ntaub ntawv.

2.Naturally balanced runner desgin, Pwm Cavity sib npaug.

3.Suitable loj ntawm Kub Nozzle tuaj yeem paub tseeb tias cov yas yaj txawb tau zoo thiab pwm kab noj hniav tau sau tusyees.

4. Kho lub rooj vag qauv thiab qhov loj tuaj yeem lav cov pwm kab noj hniav sib npaug, lub rooj vag valve kaw lub sijhawm, kom luv lub sijhawm voj voog.

5. Tsis muaj lub kaum sab xis tuag hauv kev sib tw, lav kom hloov cov xim sai sai, zam cov ntaub ntawv degration.

6. Txo qhov siab poob

7. Kev tswj xyuas lub sijhawm yog tsim nyog.

Cov khoom luam tawm

Qhia txog kev hloov pauv txawv teb chaws kub khiav cua sealing accessories!

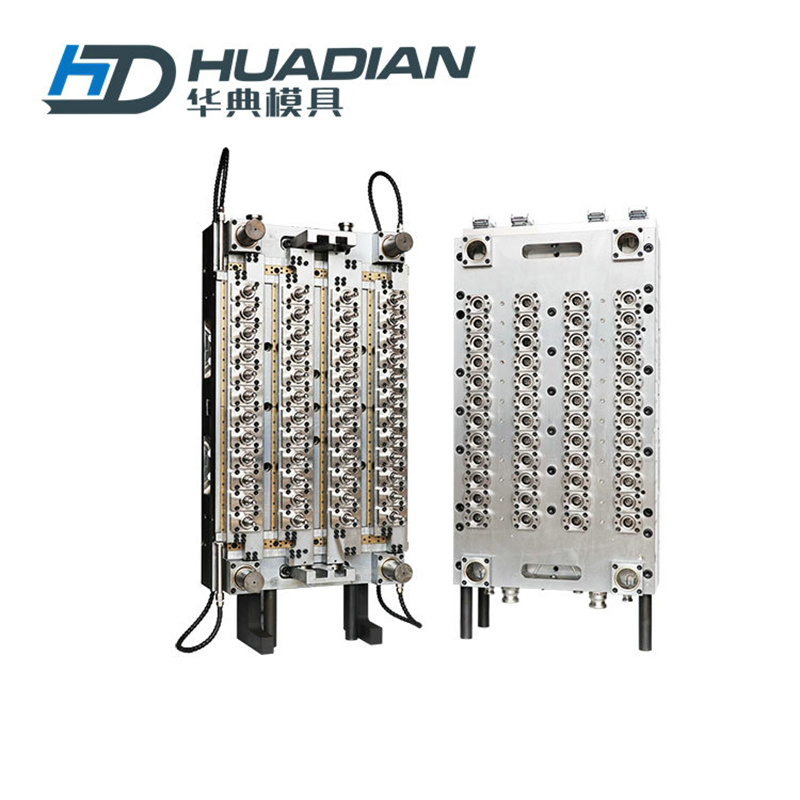

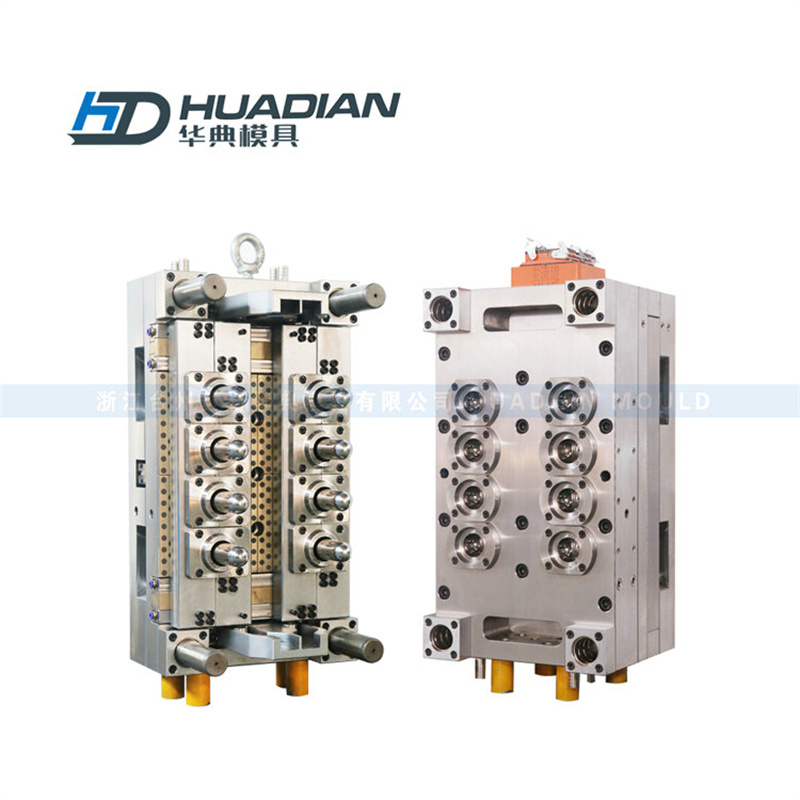

Peb txaus siab los qhia peb cov khoom tshiab tshiab, tuaj txawv teb chaws kub khiav cua foob accessories!Precision engineered thiab kev ua tau zoo optimized, cov khoom siv no yuav hloov pauv qhov kev lag luam preform pwm.Ua ke nrog lo lus tseem ceeb "Zoo 72-kab kab noj hniav preform pwm", peb cov khoom siv txiav ua tau zoo phim koj cov kev xav tau molding.

Ib qho ntawm cov yam ntxwv zoo tshaj plaws ntawm peb cov khoom siv hluav taws xob txawv teb chaws yog lawv lub peev xwm ua kom sov thiab ruaj khov.Kev tsim kho siab heev ntawm cov khoom siv no ua kom ntseeg tau tias txhua qhov preform yog rhuab sib npaug, ua rau molding zoo ib yam thiab cov khoom zoo tshaj.Tsis tas li ntawd, peb cov khoom siv muaj qhov tseeb thiab muaj peev xwm ua kom muaj cua sov zoo, ua kom cov txheej txheem tsim khoom seamless thiab ua kom koj lub lag luam tsim tau zoo.

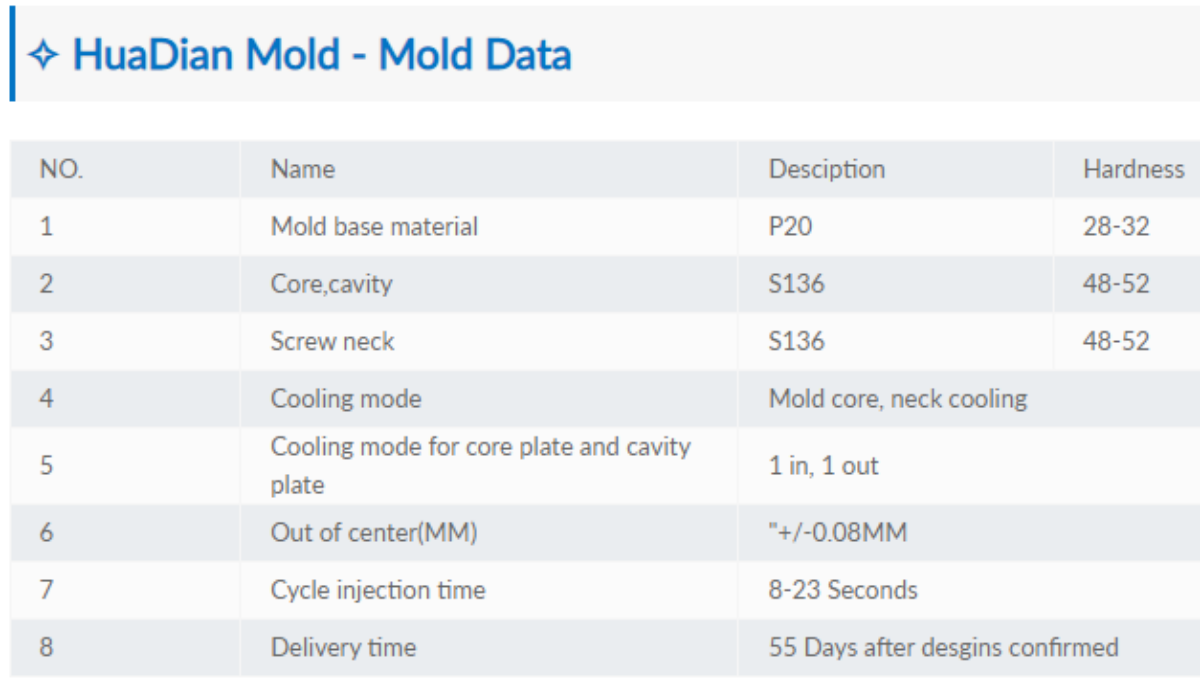

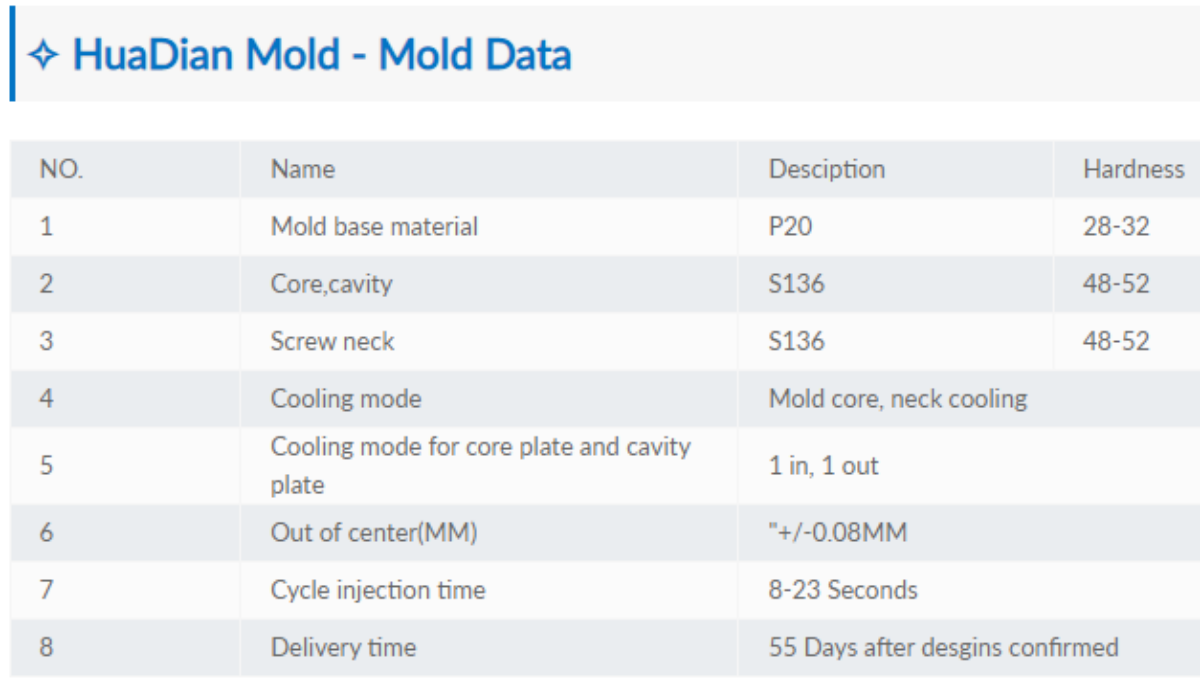

Ntawm Huadian Mould, peb txaus siab rau peb tus kheej ntawm kev muab cov pwm tsim nyog yam tsis muaj kev cuam tshuam rau qhov zoo.Los ntawm peb cov kev pabcuam zoo, peb siv zog ua kom dhau koj qhov kev cia siab thiab ua tau raws li koj cov kev xav tau tshwj xeeb.Ua tsaug rau peb txoj kev mob siab rau kev nruam ntej, kev ua tau zoo thiab tsis muaj qhov tsis zoo, peb lub tuam txhab kev muag khoom tau loj hlob tsis tu ncua txhua xyoo.Cov neeg siv khoom txaus siab yog qhov tseem ceeb ntawm txhua yam peb ua, thiab peb xyuas kom meej tias xaiv Huadian Mould yog qhov kev txiav txim siab koj yuav tsis khuv xim.

Txhawm rau ua pov thawj peb txoj kev mob siab rau kev ua tau zoo, peb siv cov txheej txheem kev kho cua sov kom raug thiab raug rau cov khoom siv hluav taws xob txawv teb chaws.Cov txheej txheem zoo tib yam no txo cov khoom seem distortion thiab xyuas kom meej thiab raug ntawm cov txiaj ntsig.Nrog peb cov khoom siv, koj tuaj yeem cia siab tias tsim tau zoo kawg nkaus preforms rau cov qauv kev lag luam siab tshaj plaws.

Nyob rau hauv luv luv, peb txawv teb kub khiav cua foob accessories muab unparalleled cua sov muaj peev xwm los xyuas kom meej uniformity, stability thiab efficiency ntawm koj preform pwm ntau lawm.Huadian Mould muab kev sib koom tes uas dhau mus dhau kev lag luam nrog tus nqi tsim nyog thiab kev xav zoo.Peb siv zog tsis yog los ua koj tus neeg muag khoom ntseeg siab xwb, tab sis kuj yog koj tus phooj ywg, txhawb kev sib raug zoo thiab ua kom koj txaus siab.Thov tso siab rau Huadian Mould, peb yuav ua haujlwm ua ke kom ua tiav cov txiaj ntsig zoo rau koj cov pwm ua ntej.